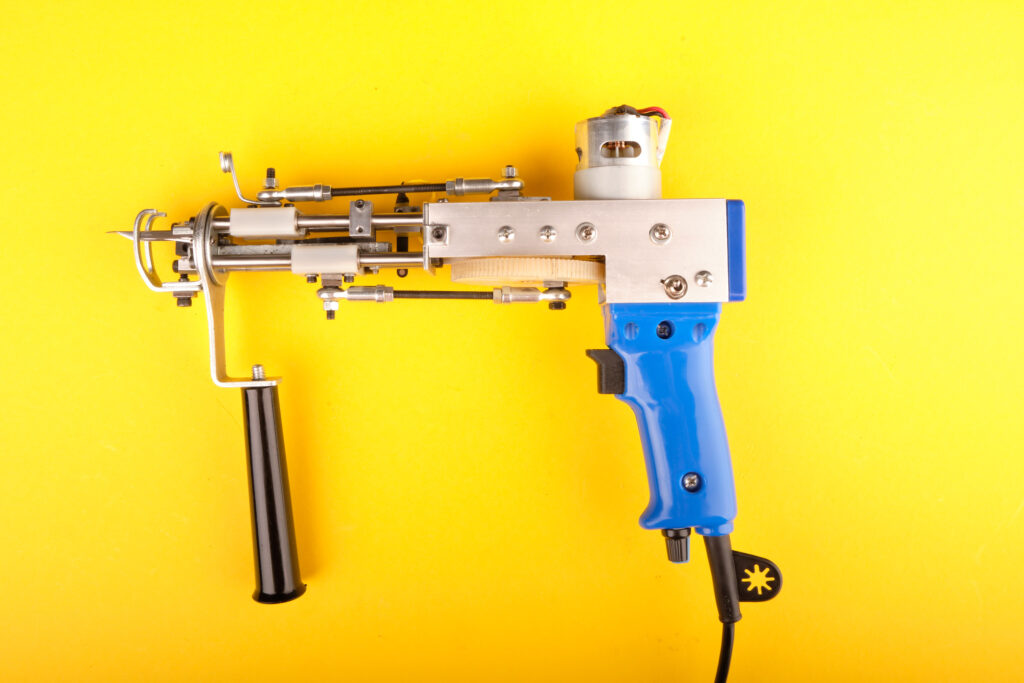

Cut Pile NK01 Tufting Gun: Pile Height Adjustment Tutorial

Here you can find a step by step manual on how to change the pile height to highest and to the lowest possible settings on our cut pile NK01 Tufting gun.

If you have problems with an uneven weave after adjusting, follow this link for troubleshooting

You may also watch the video or download the PDF at the end of each chapter.

This tutorial will teach you how to go from lowest (7mm) to highest (17mm)

Before you start, please unplug your tufting gun for your own safety!

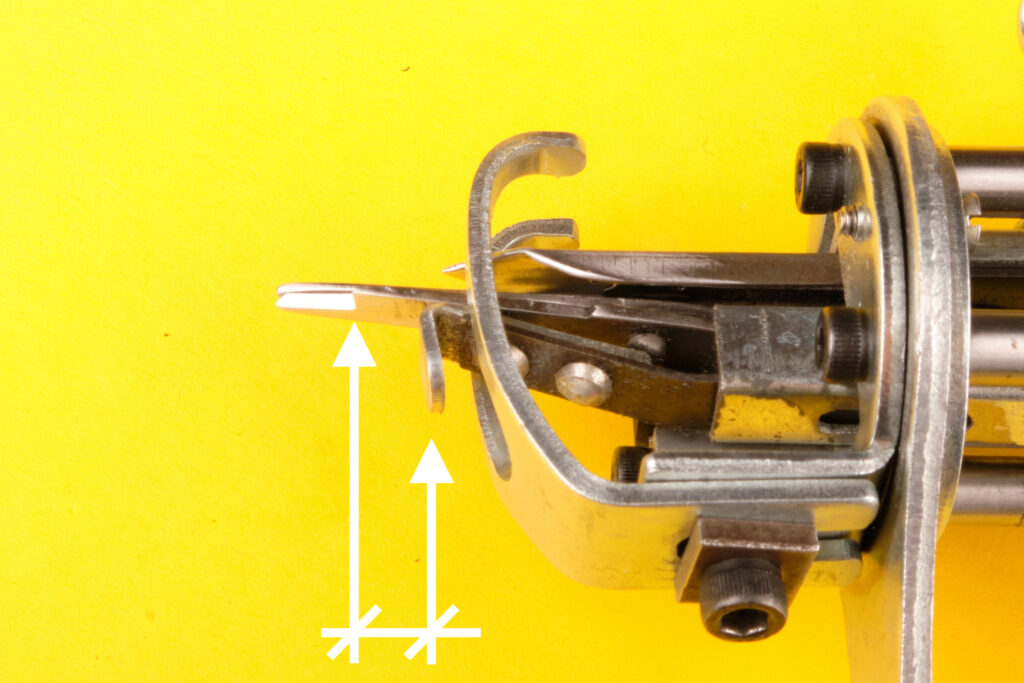

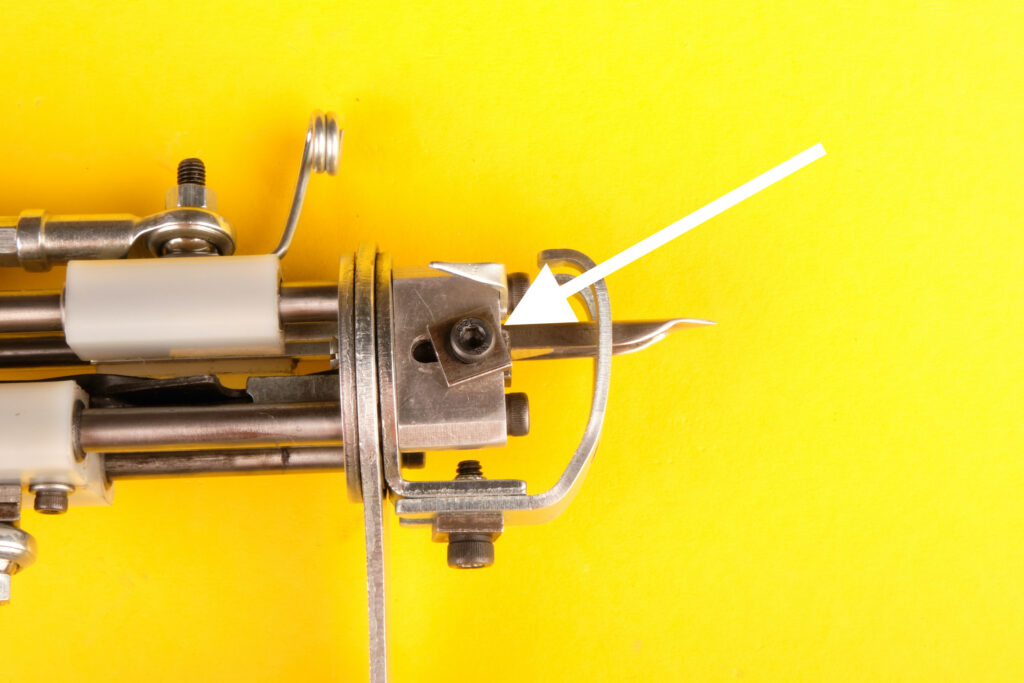

The distance between the edge of the scissors and the pusher sets the pile height. So we first want to bring this distance to our desired pile height.

Now set the pusher to the correct position. You can measure this from the edge of the scissor to the pusher front. Set it for the lowest pile to 7 mm or for the highest to 17 mm, fully to the back.

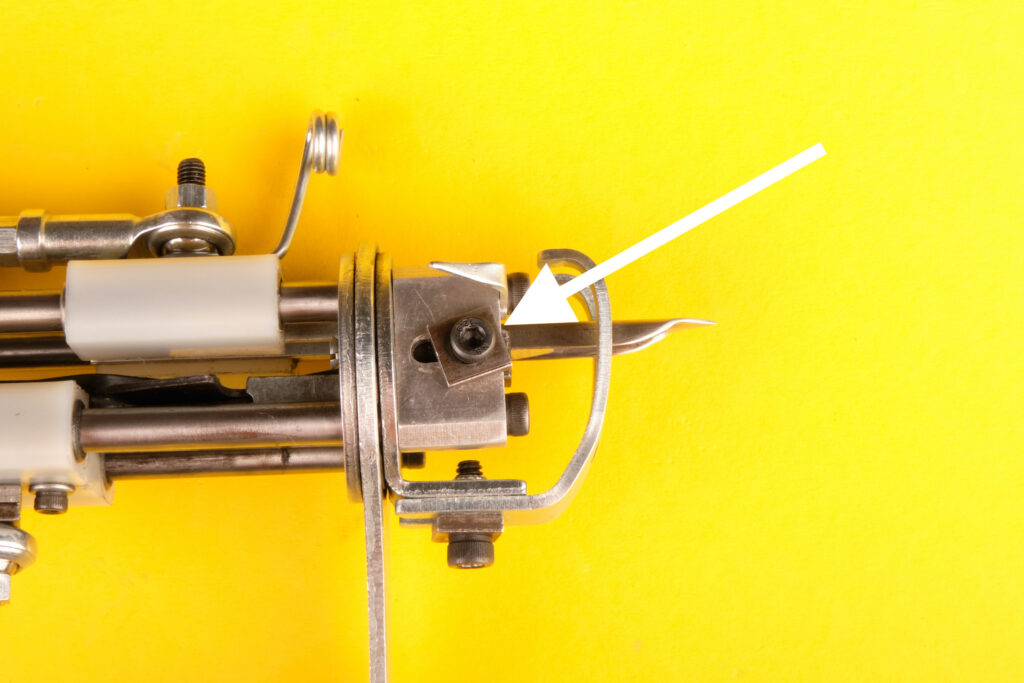

Tighten it again.

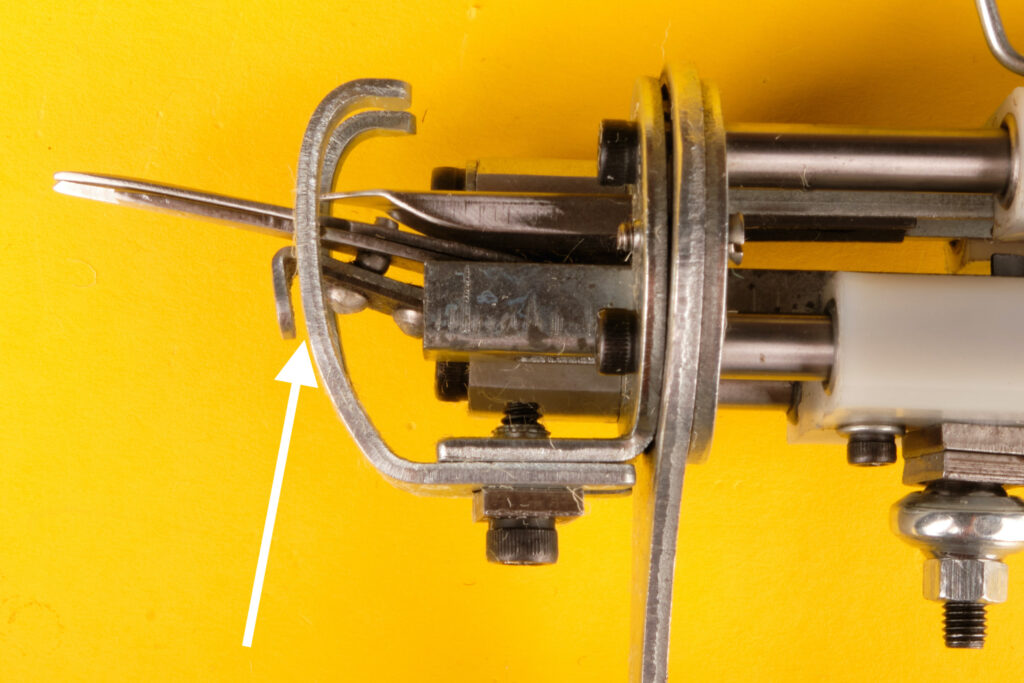

If you are going from low to high you already want to loosen the scissor mechanics screw in the back of your gun to be able to turn your gear. Just loosen it so it can move. We adjust this part later.

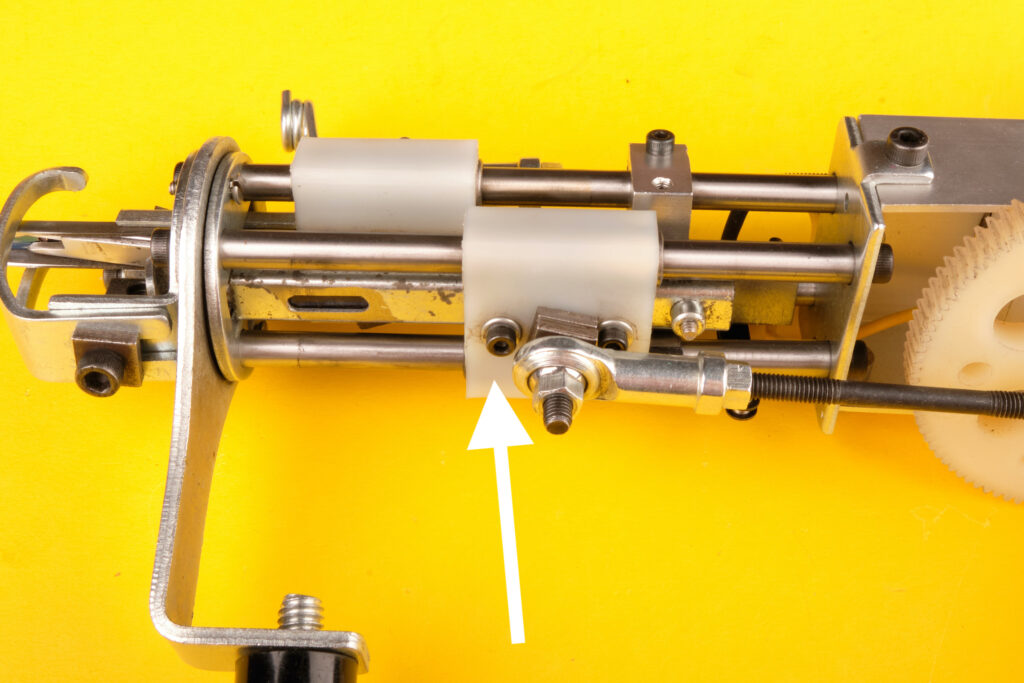

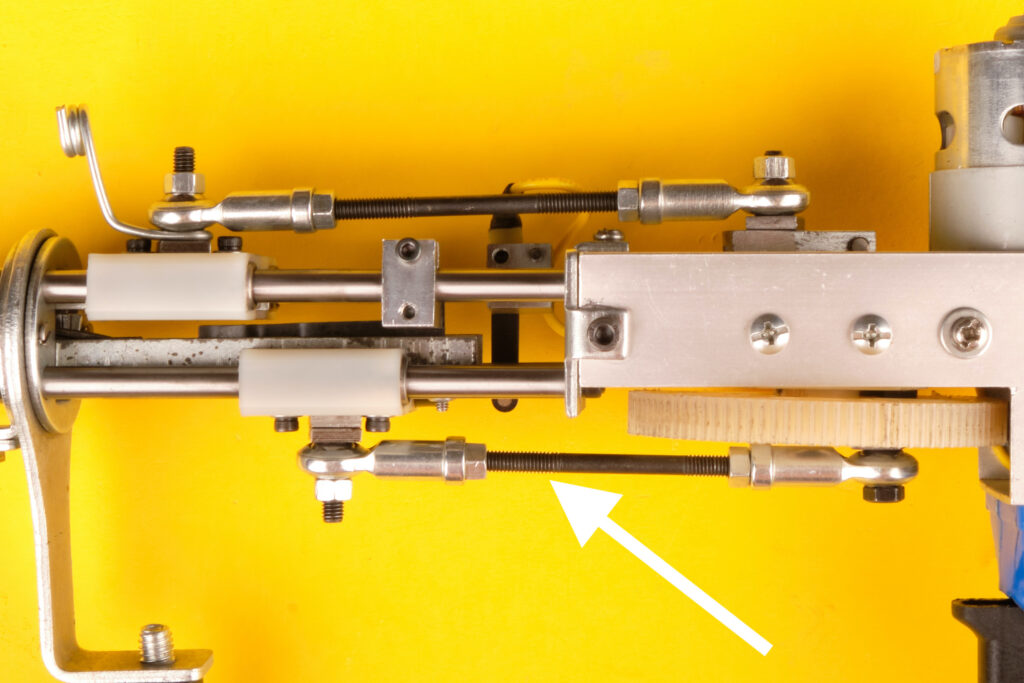

Now we want to make sure the space between pusher and foot is set correctly. We aim for 1-2mm. This can be easily checked with your smallest allen key. (WE DO NOT ADJUST THE FOOT. This has to stay aligned with the hole of the needle, otherwise you will end up with an uneven weave. Read more on this here.)

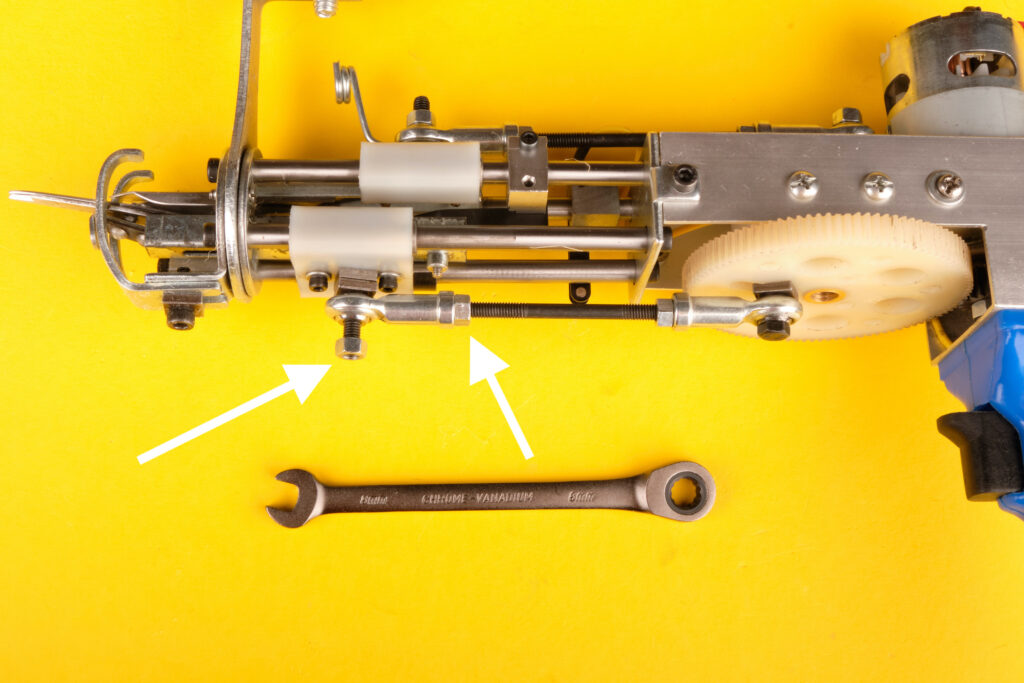

To adjust this distance we move to the bottom bearing. You want to lengthen or shorten the distance, depending on your gap. Distance for the highest pile would be around 52mm, distance for the lowest pile would be around 44mm.

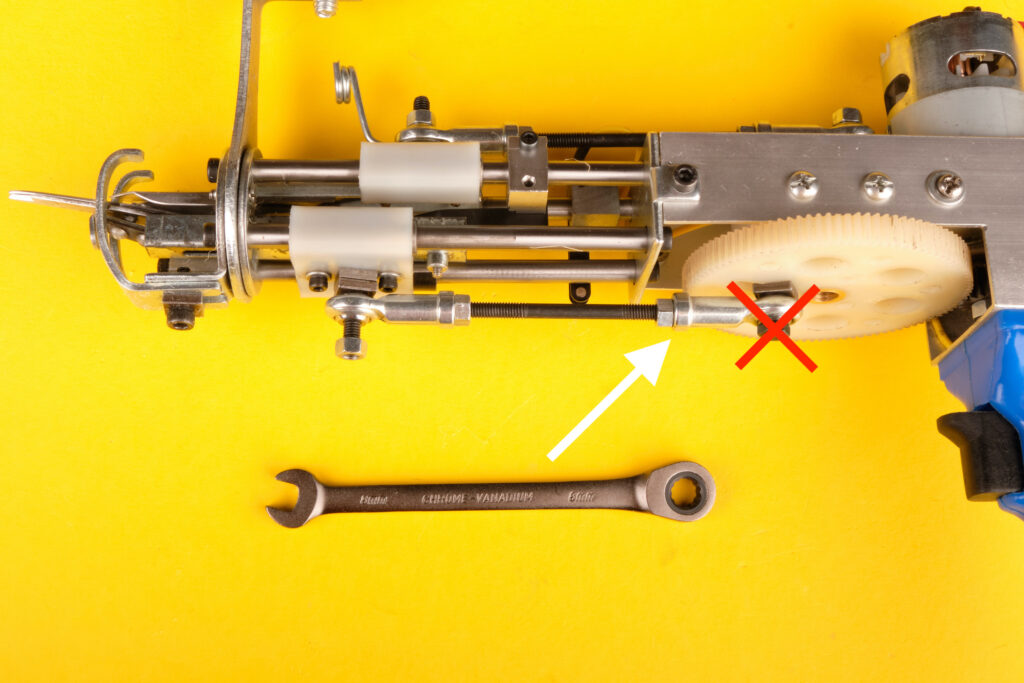

If you can’t shorten or lengthen it enough, loosen the screw of the rod on the gear end as well. DO NOT UNSCREW THE NUT THAT ATTACHES TO THE GEAR!

You can alway check for the correct adjustment by putting on the front rod again and turning your gear, so you can see if the distance between the pusher and the foot is set correctly. Once your distance is set and the placement of the pusher is correct, tighten all the nuts properly.

If you have adjusted your pile height of your cut pile NK01 Tufting gun you need to adjust the scissor closing mechanism as well.

To adjust this you want to loosen the screw on the backside of your gun on the side of the foot, with your middle allen key. With sliding this screw you can adjust the closing mechanism. When you’re going for the longest pile height you want to go to the very front and for the smallest to the very back. This needs some trial and error sometimes as well.

If you set it to the shortest pile height and the scissors are not closing, first check your standard setting. As soon as they are correct, lengthen the lower bearing by 1-2 mm.

What are the factory lengths of the top bar and bottom bar? I watched one tutorial and the instructor said to modify the top and never the bottom. I did so and the cut pile didn’t seem to change. Now my gun has a slight amount of tension when the scissors are retracting back to a full resting position. Please help

Hey Taylor,

you can find all the standard settings of our NK01 in this article here https://bit.ly/3urwEwR in our NK01 Overview Tutorial.

I hope this solves your problem. If not don’t hesitate to write us again!

Have a nice weekend

Jenni from Tuftinglove

Retightening the screw on the underside does not seem to have immobilized the pusher in its newly adjusted position! Have I broken something? Very worried. Even with the screw as tight as I can get it, the pusher can be easily removed from the front of the gun.

Hello! I’m having an issue with the pusher, it’s actually falling out of the gun while tufting. I’ve tried screws and whatnot but nothing is seeming to work. What would be causing the entire pusher to fall out of the gun completely?

Hey Jacob,

you most probably unscrewd it too far. Follow the how to change the scissors tutorial to reach the counterpart underneath the scissors and fix in place again.

Dear, I followed the instruction video to change the pile height but I’m unable to fasten a screw again. It’s the screw from this step: “Loosen the screw on the bottom of your gun with the smallest allen key to make the pusher movable.” The screw doesn’t fasten anymore, it just keeps turning. How can this happen? And how can I fix this? Thank you!

Hey Liza,

you most probably turned it out too much. You can follow the scissors changing tutorial, take out the scissors and you will find the counterpart underneath it.